In the preventive testing of power equipment, the power frequency AC withstand voltage test and the frequency conversion series resonance withstand voltage test are the two core methods for verifying the insulation strength of the equipment. The former directly uses 50Hz power frequency voltage to simulate the actual operating conditions of the equipment; The latter adjusts the frequency to generate resonance in the circuit, significantly reducing the capacity requirement of the test power supply. In traditional homework, the two are often carried out independently, but if their advantages are combined, the efficiency of the experiment will be revolutionized!

1、 Basic analysis: What are the two core experimental techniques?

Power frequency AC withstand voltage test

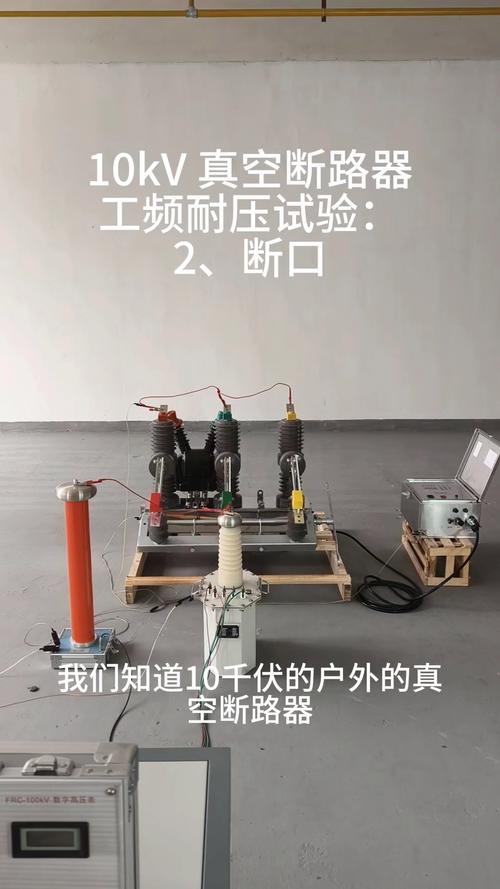

This is the most direct test method for simulating the operating voltage of equipment, especially suitable for verifying the insulation strength of equipment such as transformers, motors, busbars, and bushings. During the experiment, it is necessary to apply AC power higher than the rated voltage to the equipment (such as the power frequency withstand voltage test of 35kV switches or 110kV transformers) for a specified period of time to detect insulation defects.

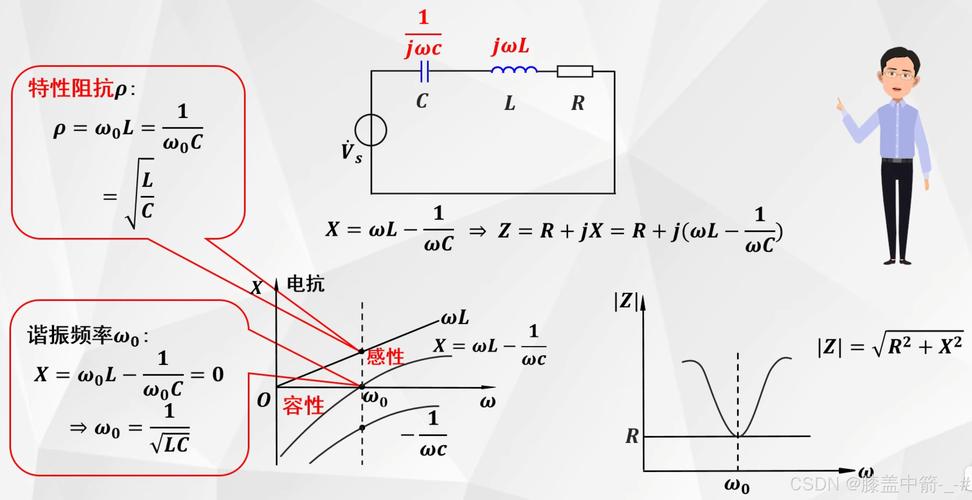

Variable frequency series resonance withstand voltage test

For high capacitance load equipment such as long cables (such as 110kV/3KM), GIS equipment, and large generators (600MW level), traditional power frequency testing requires a large power supply equipment. Series resonance technology adjusts the output frequency of the variable frequency power supply to resonate the reactor with the capacitor of the test sample. It only needs to compensate for the circuit resistance loss, and the power supply capacity can be reduced to 1/5-1/10 of the conventional level, which is particularly suitable for on-site testing.

2、 Efficiency bottleneck: four key factors affecting the efficiency of high-voltage testing

Time consumption for device switching

When the power frequency test device is separated from the resonance device, changing and rewiring the cables consumes a lot of time, especially for GIS multi interval or long cable segmented testing.

Power capacity limitation

Large capacity equipment (such as generators with phase capacitance above 0.25 μ F) requires heavy-duty voltage regulators for power frequency withstand voltage, which is difficult to transport and complex to debug. Although resonant devices are lightweight, they cannot meet the economic needs of small capacity equipment.

Test cycle redundancy

Splitting the test into two means repeatedly boosting, recording data, and disassembling equipment. There may be a risk of differences in the insulation status of the same equipment between the two tests.

Personnel collaboration cost

The experimental team needs to master two types of equipment operation specifications separately, which incurs high training costs, and alternating operations can easily lead to safety hazards due to communication errors.

3、 Technology integration: How to achieve "1+1>2" between power frequency and frequency conversion resonance?

The new generation integrated testing device integrates the power supply and frequency conversion resonance module into an integrated platform through an intelligent switching unit. Taking Wuhan Ultra High Voltage Power Technology Co., Ltd.'s solution as an example, its equipment supports the following innovative collaborations:

Automatic mode switching

The same set of reactors (such as 22kV/40kV modules) can be used to test 110kV cables in frequency conversion mode, or to switch back to power frequency mode to verify 35kV switch withstand voltage without disconnecting the wires.

Maximizing Resource Reuse

The parallel configuration of reactors (such as 4 × 22kV) enables flexible expansion of voltage and current, adapting to the wide spectrum requirements from 10kV short cables to 500kV transformers.

Intelligent pre diagnosis

Combined with the partial discharge testing system, the amount of partial discharge is synchronously monitored during the withstand voltage process to detect potential defects in advance and avoid repeated voltage boosting.

✅ Case study: A certain substation conducts annual maintenance on 110kV GIS. The traditional method requires testing the transformer with a power frequency device (2 hours) first, and then testing the main busbar with a resonant device (3 hours). After adopting the Wuhan ultra-high voltage integrated system, the mode switching only takes 10 minutes, the total time is compressed to 3.5 hours, and the efficiency is improved by 42%.

4、 Efficiency Leap in Practical Practice: Four Step Optimization Test Process

Planning phase: Dynamic planning of experimental path

Automatically recommend test modes based on equipment type (such as transformer/cable/GIS). For example:

Generator withstand voltage → priority resonance mode (large capacitance, compensation required)

10kV switchgear → power frequency mode (easy to operate)

Tool support: Pre installed software for experimental plans to reduce manual decision-making time

Wiring stage: Universal interface design

Adopting standardized multifunctional testing terminal boxes, all test samples (circuit breakers, transformers, cable terminals) are connected to the same interface group to avoid repeated disconnection.

Execution phase: seamless integration of dual modes

First, use resonant mode to complete the AC withstand voltage of high-voltage cables

Switch to power frequency mode and immediately perform partial discharge detection on cable terminal sleeves

Tool support: Built in automatic frequency tracking and power frequency phase-locked module

Analysis stage: Data fusion diagnosis

Integrate withstand voltage data with insulation resistance testing and dielectric loss results to generate multi-dimensional reports on equipment insulation status, significantly reducing retesting rates.

5、 Key technological tool: the 'behind the scenes hero' of efficiency revolution

Intelligent reactor cluster

Modular design (such as 22kV/unit) supports free series and parallel connection, portable and adaptable to different voltage levels (10kV-500kV).

Broadband power platform

The output frequency ranges from 0.1-300Hz, covering the requirements of power frequency to ultra-low frequency. One set of power supply meets the requirements of power frequency withstand voltage test, frequency conversion resonance test, and ultra-low frequency withstand voltage test.

Cloud Collaborative Management System

Real time upload of experimental data, supporting remote expert diagnosis, especially suitable for complex scenarios such as transformer comprehensive testing.

Industry benchmark practice: Wuhan Ultra High Voltage Power Technology Co., Ltd., which has been deeply involved in the field of high-voltage testing for nearly 20 years, has successfully applied its integrated system to multiple ultra-high voltage projects. By combining power frequency stability with resonance economy, the withstand voltage test time of 600MW generators has been shortened from 8 hours to 3 hours, reducing power capacity requirements by 80%.

6、 Future direction: Integration of intelligence and standardization

AI predictive testing

Based on historical data, predict the trend of equipment insulation degradation, dynamically adjust the withstand voltage test cycle, and reduce ineffective tests.

Unmanned experimental cabin

Integrate robot wiring and automatic safety protection to achieve unmanned operation in dangerous areas such as GIS rooms.

International standard integration

Promote the recognition of composite testing modes by IEC and national standards, and accelerate the promotion of technology.

Frequently Asked Questions (FAQ)

Q: Which is more stringent, power frequency or resonant withstand voltage?

A: The strictness depends on the test voltage value rather than the frequency. The power frequency is closer to the operating conditions, and resonance can apply higher voltage to high capacitance equipment. The complementarity of the two can cover a more complete defect spectrum.

Q: Can resonant devices completely replace power frequency equipment?

A: Not recommended. Small capacity equipment (such as 10kV transformers) using power frequency devices is more economical; And some standards (such as transformer induction withstand voltage) explicitly require power frequency.

Q: Does mode switching affect the safety of the experiment?

A: The integrated system has built-in locking logic, which automatically discharges and grounds during switching, making it safer and more reliable than manual switching.

Q: How to choose a reactor configuration?

A: Calculate the capacitance of the test sample (e.g. approximately 0.1 μ F/km for a 110kV cable). Generally, the reactance is matched according to the formula L=1/(4 π² f ² C). It is recommended to consult a professional manufacturer for selection.

Q: Can the joint experiment pass regulatory acceptance?

A: Domestic standards such as DL/T 849-2024 have been released to recognize the equivalence of resonant withstand voltage, and the fusion scheme complies with the testing and repair specifications.